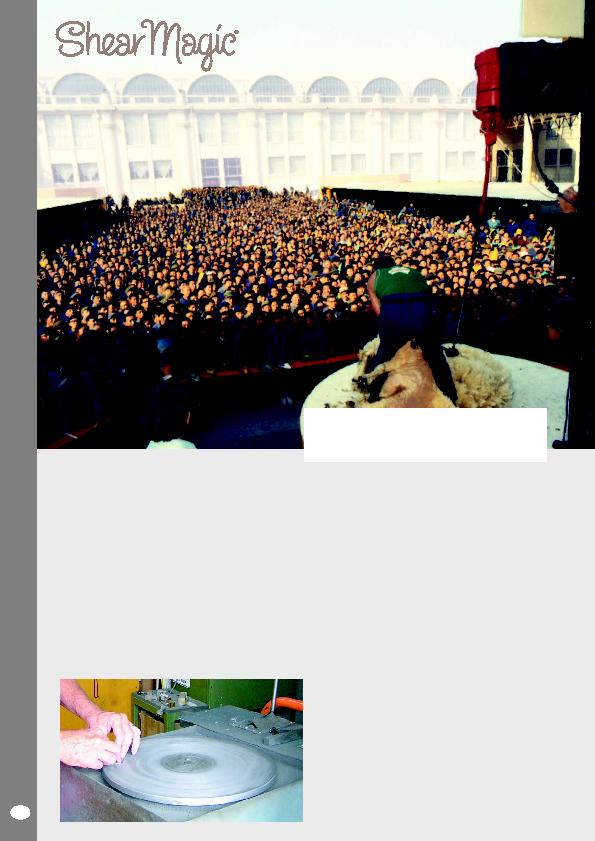

John Allan OAM. John was awarded the Order of Australia for his contribution to the wool industry and spent his

life designing and improving clipping equipment. Shear Magic continues to design and manufacture clippers that are

operator friendly, built to last and deliver great value.

keep your clipper running cooler with less stress. Professional users

often have more invested in blades than any other grooming item, and

a professional sharpening service can extend the life of the blades and

guarantee a sharp cut every time.

utilise highly trained and experienced professionals, the latest in sharp-

ening technology and rigorous quality control measures.

move any rust or corrosion, checking the spring and slide bar for wear

or damage and assessing the blade surfaces for wear or broken teeth.

ing wheels. Hollow grinding can only be achieved on these machines

and creates a longer lasting sharp edge, and helps keep blades running

cooler and sharper for longer.

there is exactly the right amount of tension applied to the blade cut-

ting surfaces. Too little tension and the blades won't cut, too much

and the blades will dull quickly and cause the clipper to work harder.

Once the blades are re-assembled they are oiled and every blade is

tested on kangaroo fur prior to packaging for transport.

you are not totally happy with the service you receive, we'll fix it, no

problems.

bar, and how blades are reassembled. Always send complete blade

sets, wrapped individually to prevent damage.

and drives the blade from side to side. This will wear over time and

then won't move the cutter bar enough to cut efficiently.

can test your blades on prior to returning them to you.

ing during storage and will extend the cutting life of your blade.

Always dry the blade before storage.